CNC Machining of Stainless Steel Parts: A Comprehensive Guide

Release time:2024-03-26 Click:325

CNC Machining of Stainless Steel Parts: A Comprehensive Guide

In the modern manufacturing industry, CNC (Computer Numerical Control) machining plays a vital role in producing high-quality stainless steel parts. This advanced manufacturing technique offers precise and efficient production, enabling the creation of complex components with exceptional accuracy. In this article, we will explore the process of CNC machining of stainless steel parts, highlighting its benefits, applications, and key considerations.

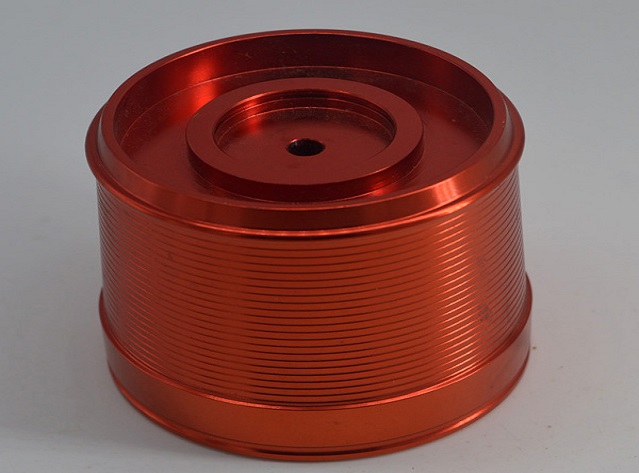

CNC machining utilizes computerized instructions to control the movement of machine tools, allowing for the fabrication of stainless steel parts with intricate designs and tight tolerances. The process begins with the selection of suitable stainless steel alloys, which offer durability, corrosion resistance, and mechanical properties suitable for various applications.

The CNC machine tools used in stainless steel machining are equipped with high-speed spindles, cutting tools, and sophisticated software. These tools enable the milling, drilling, turning, and other machining operations required to shape the stainless steel into the desired parts. The precision and repeatability of CNC machining ensure consistent quality

across multiple productions.

One of the significant advantages of CNC machining is its ability to handle complex geometries. Whether it's internal channels, threaded holes, or delicate features, CNC machines can fabricate stainless steel parts with ease. This flexibility opens up possibilities in a wide range of industries, including aerospace, automotive, medical, and consumer goods.

Stainless steel's corrosion resistance makes it ideal for applications in harsh environments or where exposure to moisture and chemicals is a concern. CNC machining allows for the production of parts that meet these demanding requirements, ensuring long-lasting

performance and reliability.

During the CNC machining process, attention to detail is

crucial. Factors such as cutting speeds, feed rates, and tool selection affect the quality and efficiency of the operation. Skilled machinists and engineers optimize these parameters to achieve the best results, minimizing material waste and maximizing productivity.

To ensure the integrity and accuracy of the final parts, quality control measures are implemented throughout the manufacturing process. Inspections, dimensional checks, and

surface finish evaluations are conducted to meet stringent industry standards.

In conclusion, CNC machining of stainless steel parts offers a reliable and efficient means of producing high-quality components. With its precise control, ability to handle complex geometries, and corrosion resistance, this technique is widely utilized in diverse industries. By understanding the process and considering key factors, manufacturers can harness the power of CNC machining to create

superior stainless steel parts that meet the demands of various applications. Whether for small-scale productions or large industrial projects, CNC machining provides a tailored solution for the fabrication of stainless steel components.