CNC Turning for Gear Parts: Precision Manufacturing at Its Finest

Release time:2024-03-26 Click:300

In the world of manufacturing, gear parts play a crucial role in various mechanical systems. Whether it's in the automotive industry, aerospace, or any other field that relies on precise and efficient machinery, the quality of gear parts is of utmost importance. CNC turning, with its advanced technology and precision, has emerged as a preferred method for manufacturing high-quality gear parts.

CNC turning is a process where a computer numerically controlled (CNC) lathe is used to shape metal or other materials into the desired form. This technique offers several advantages over traditional machining methods. The CNC machine ensures high accuracy and repeatability, allowing for the production of gear parts with intricate geometries and tight tolerances. The use of CNC turning enables manufacturers to achieve exceptional surface finishes, enhancing the performance and lifespan of the gears.

One of the key benefits of CNC turning for gear parts is the ability to produce complex shapes. Gears often have specific tooth profiles and geometry requirements, and CNC turning can handle these complexities with ease. By programming the machine with detailed instructions, it is possible to create gears with custom designs, ensuring optimal functionality and compatibility with the intended application.

CNC turning also offers greater flexibility in terms of material selection. Different gear applications may call for specific materials with unique properties such as strength, durability, or resistance to wear and corrosion. Whether it's steel, aluminum, alloys, or other metals, CNC turning can accommodate a wide range of materials, enabling the manufacture of gear parts tailored to specific performance needs.

In addition to complexity and material flexibility, CNC turning provides efficient production. The automated nature of the process allows for high-volume manufacturing, reducing lead times and increasing productivity. This is particularly beneficial in industries where large quantities of gear parts are required.Moreover, CNC turning lends itself well to mass customization, enabling the production of gears with varying specifications to meet individual customer demands.

Quality control is a top priority in gear part manufacturing, and CNC turning aids in this aspect as well. Advanced monitoring systems and sensors integrated into the CNC machines can detect any deviations or flaws during the turning process. This enables real-time adjustments to ensure that each gear part meets the strictest quality standards.

In conclusion, CNC turning has revolutionized the manufacturing of gear parts. It offers precision, complexity, material flexibility, efficiency, and quality control, all of which are essential in producing superior gear components. As the demand for precise and reliable machinery continues to grow, CNC turning will remain at the forefront of gear part manufacturing, driving innovation and delivering excellence in performance.

Hot products

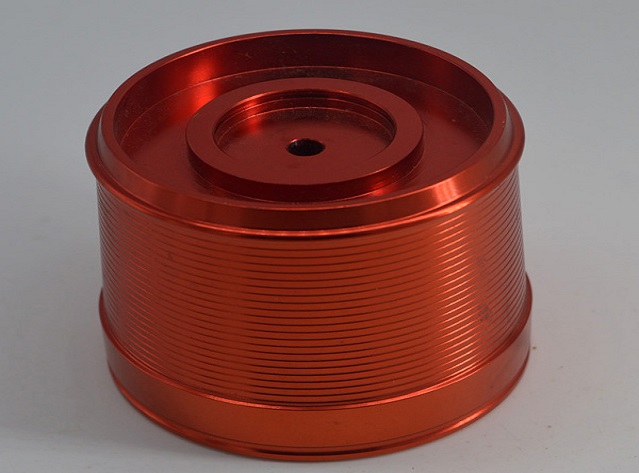

Parts of Spinning Reel

Parts of Laser Sword

CNC Machining Non-Standard Custom Parts

Upgrade Metal Parts Rear Shock Plate for Desert Truck

Tel:15916948886

E-mail:ken.tang@chengcg.com , ken13608@gmail.com